product categories

-

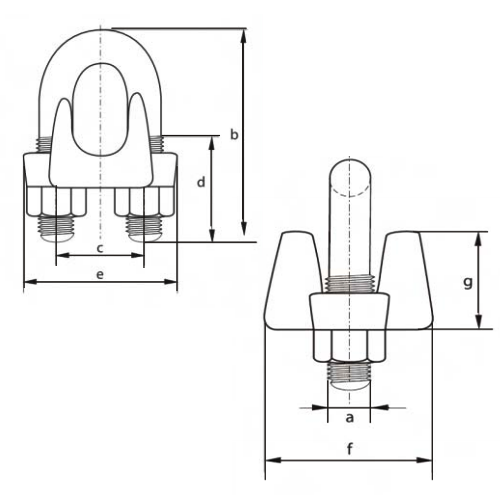

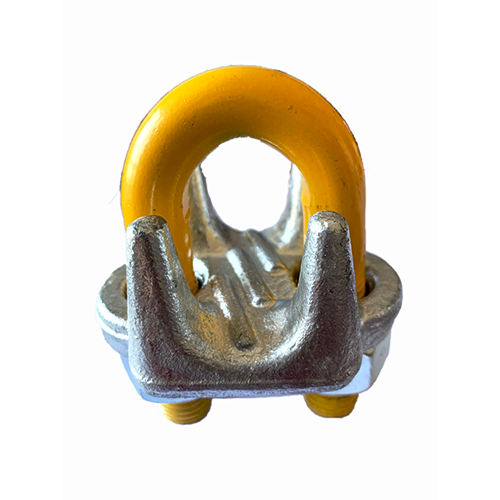

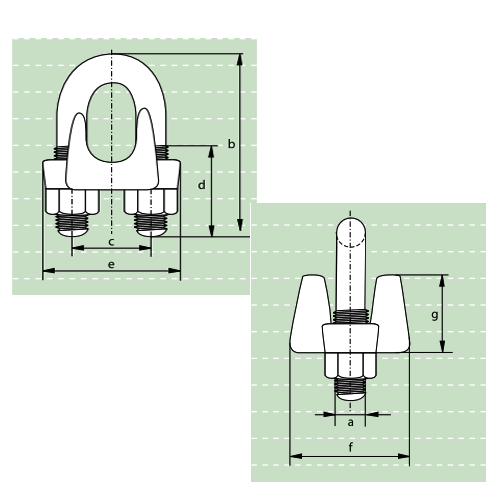

- Wire rope clips are used on wire rope eye-loop connections or complete loops, end-to-end connections where socketing or splicing is not feasible or when a temporary joint is required.

- Ableforge offers a wide range of wire rope clips, specifically standardized models such as EN 13411-5 and DIN wire rope clips.

-

- Wire rope clips are used on wire rope eye-loop connections or complete loops, end-to-end connections where socketing or splicing is not feasible or when a temporary joint is required.

- Van Beest offers a wide range of wire rope clips, specifically standardized models such as EN 13411-5 and DIN wire rope clips.

-

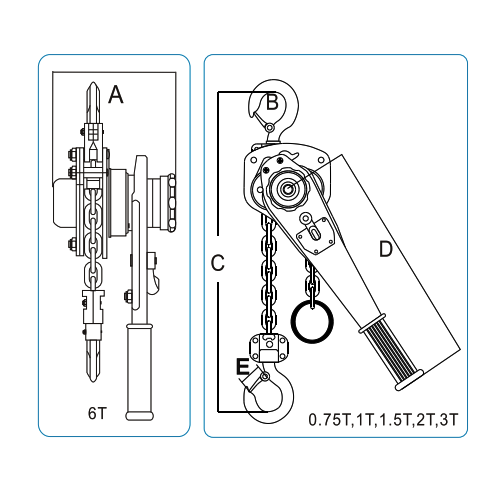

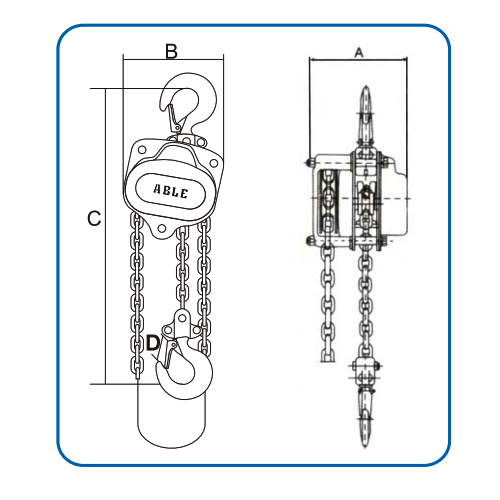

- Standard: BS EN 13157

- WLL < 5ton, 100% load tested to 1.5 x WLL

- WLL ≥10ton, 100% load tested to 1.25 x WLL

- Safety factor 4:1

- Grade 80 alloy load chain. Elongation ≥ 10%

- Forged and Heat Treated load Hooks with ABLE mark and stretch indicators

- Load sheave with sealed roller bearing.

- Anchor plate avoiding overlowering.

-

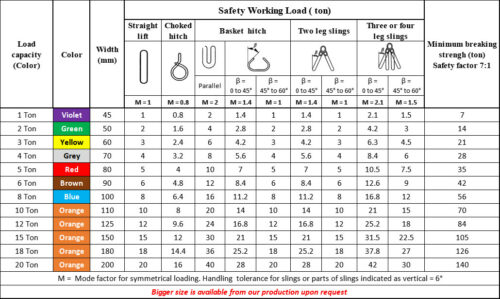

- According to EN 1492-2.

- Each stripe is equal to 1 Ton capacity.

- Material: 100% hight tenacity polyester of out sleeve and inner core

- With two fly woven heavy duty out sleeve

- Low elongation.

- Safety factor available 7:1

- The coils are protected by “mantle” polyesters solidly.

- As one of the specialized products in the process of lifting, moving heavy goods, bulky.

- Round Sling are manufactured under strict process fully meets the technical standards with high safety factor and the ability to take big loading capacity.

-

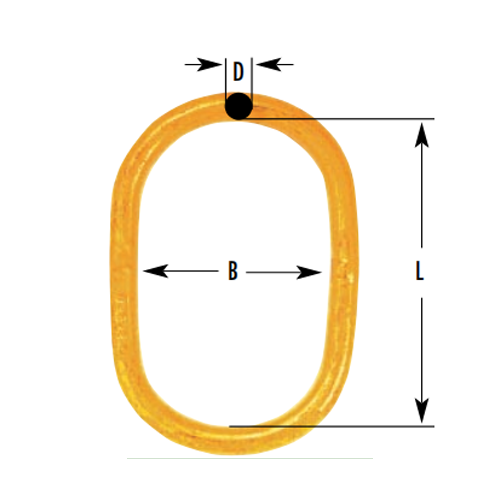

- Designed for use with chain or wire rope.

- Mekongsling specialize in supplying masterlink and masterlink assembly for fabricate wire rope slings and single and multi leg chain slings as well.

- Well suited for use with chain, wire rope, and synthetic slings.

- The products are cast from alloy steel, with high load capacity and safe for using.

- Inspection should take place at least every six months and more frequendly when the links are used in severe operating conditions.

-

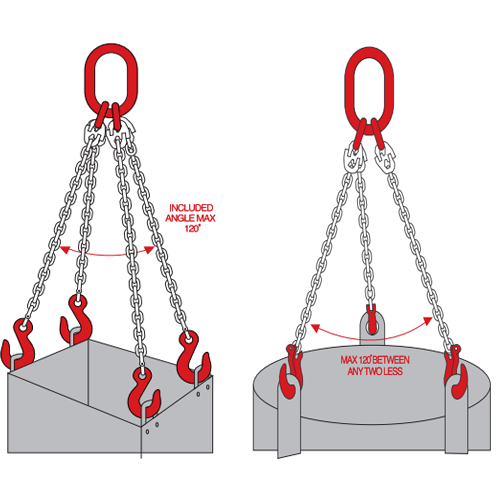

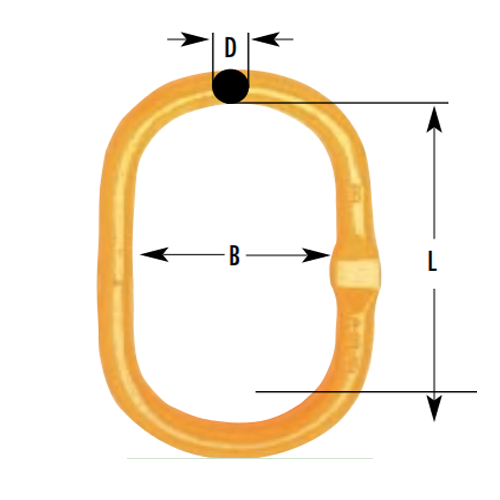

- For 1-, 2-, 3- and 4-leg slings. Designed for use with CL, CLD, CG and CGD. 3- and 4-leg chain slings require CLD / CGD.

- Mekongsling specialize in supplying masterlink and masterlink assembly for fabricate wire rope slings and single and multi leg chain slings as well.

- Well suited for use with chain, wire rope, and synthetic slings.

- The products are cast from alloy steel, with high load capacity and safe for using.

- Inspection should take place at least every six months and more frequendly when the links are used in severe operating conditions

-

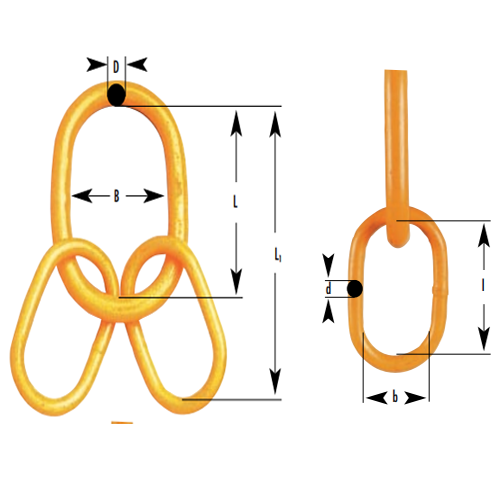

- Designed for use with chain or wire rope. For 3- and 4-leg slings.

- Mekongsling specialize in supplying masterlink and masterlink assembly for fabricate wire rope slings and single and multi leg chain slings as well.

- Well suited for use with chain, wire rope, and synthetic slings.

- The products are cast from alloy steel, with high load capacity and safe for using.

- Inspection should take place at least every six months and more frequendly when the links are used in severe operating conditions

-

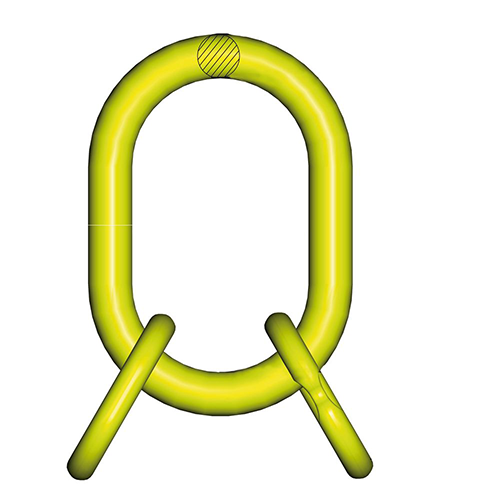

- Designed for use with chain.

- Mekongsling specialize in supplying masterlink and masterlink assembly for fabricate wire rope slings and single and multi leg chain slings as well.

- Well suited for use with chain, wire rope, and synthetic slings.

- The products are cast from alloy steel, with high load capacity and safe for using.

- Inspection should take place at least every six months and more frequendly when the links are used in severe operating conditions

-

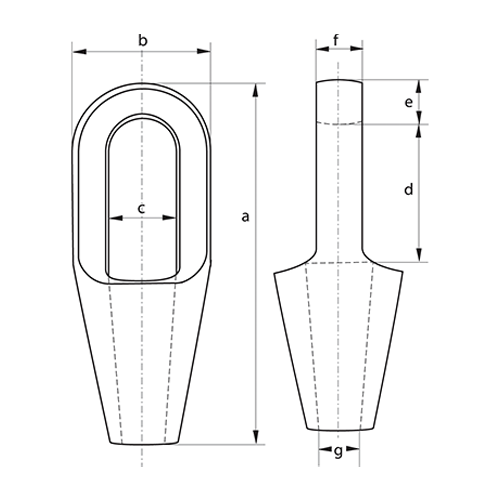

- Sockets are used to attach steel wire rope to a fixed point to which the socket is to be connected. This can be as an anchoring system for tubes or pipes, anchor wires of dredging material, anchor cables of oil platforms, towing cables or for fastening cables in construction purposes such as bridges, roof construction etc.

- Sockets are designed for in-line use only.

- Sockets are the strongest steel wire rope and fittings available. If they are assembled in the proper way the meet or exceed the breaking strength of the steel wire rope.